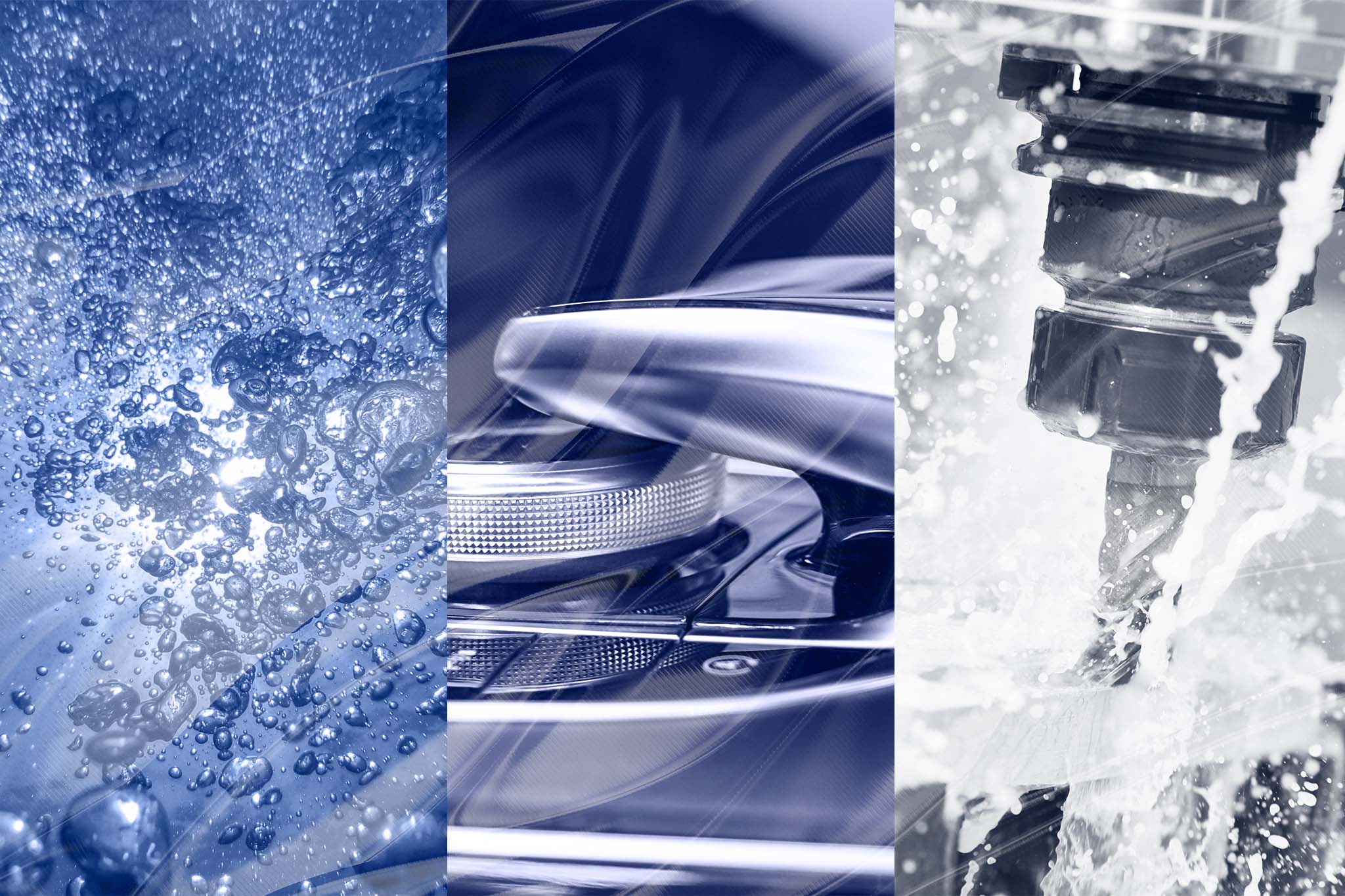

Filtered washing station

Metal recovery unit (hand and tool washing)

Combined washing station featuring a high-quality stainless steel sink and a removable filtration system on casters. This fully integrated unit ensures systematic recovery of precious metal particles during hand and tool washing. Its high-performance filtration (down to 1 μm) secures effluent discharge and maximizes precious metal recovery.

Precious Metal Recovery

The recovery system is specifically calibrated to capture micro-particles of gold, silver, or platinum from hand and tool washing.

The high-performance dual filtration (5 μm then 1 μm) with quick-access design ensures optimal recovery of fine particles and minimizes material loss.

Optimized Maintenance

The system is mounted on a mobile chassis with casters for full extraction and easy maintenance.

The robust protective casing, equipped with integrated handles, is easily removable to provide quick access to components and clean replacement of consumables.

Control Interface

Integrated enclosure managing level automation (High / Low) with immediate visual indication via Green / Red lights.

It provides automatic detection of clogging and overflow, complemented by a precision pressure gauge for safe monitoring of filter status.

Key Features

1) Pre-filtration with 50μm bag

2) Fine filtration with 5μm and 1μm cartridges in series

3) Autonomous system with lift pump

4) Pressure sensor for clogging detection

5) Mobile chassis on casters

Specifications

- Applications

- Recovery of precious metals

Design

- Materials

- Polypropylene, Stainless steel

- End

- Nut, Threaded

- Length (mm)

- 1200

- Depth (mm)

- 600

- Height (mm)

- 1033,5

Filtration

- Filtration media

- QUALITHERM™ (extruded cartridge), BAGTECH™ (Filter bag)

- Media height

- 10" (~254 mm)

- Available porosities (µm)

- 1, 5, 50

Pumping

- Flow rate (m³/h)

- 10

- Manometric height (mH2O)

- 14

- Power (W)

- 550

- Power supply

- 230V single phase