Venturi Nozzles

Bath mixing

Venturi technology guarantees energy savings and improved deposit quality, while providing a healthier working environment. Unlike traditional air agitation systems, Venturi nozzles do not introduce air - hotter or colder than the bath - but use the liquid in the bath directly to agitate it. Thus, the bath retains its thermal properties and is much less prone to evaporation.

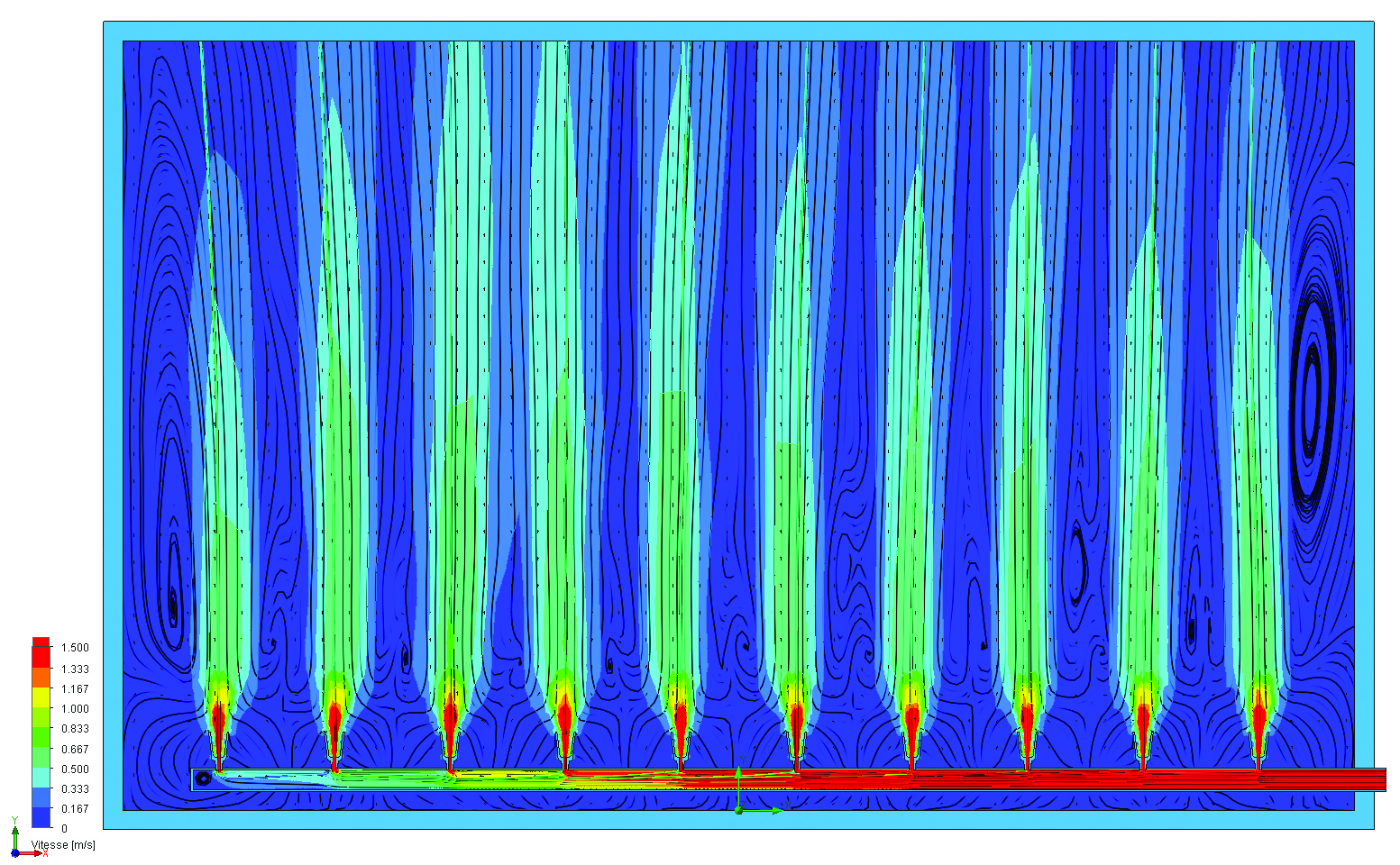

Fluid simulation

Our design office simulates the agitation of your bath on specialized software to optimize the number of nozzles needed.

Features & benefits

Limitation of evaporation

Significant reduction in bath evaporation (-90%)

Reduced costs for treatment and effluent removal.

Significant energy savings

Helps maintain the temperature of the treatment bath.

Reduction of the costs of heating or cooling the bath.

Healthier working conditions

Reduced evaporation greatly improves air quality in the process plant.

More reasons to choose venturi agitation for your bath

- Prevents bath stagnation and disperses products and reagents

- Increases the deposition factor

- Improved deposition quality with homogeneous layers

- Optimises deposition: porosity, hardness, abrasion resistance, etc.

- Heat dissipation at the cathode/electrolyte interface

The Venturi principle multiplies by 5 the volume of pumped liquid.

Specifications

- Materials

- Polypropylene, PVDF, Stainless steel