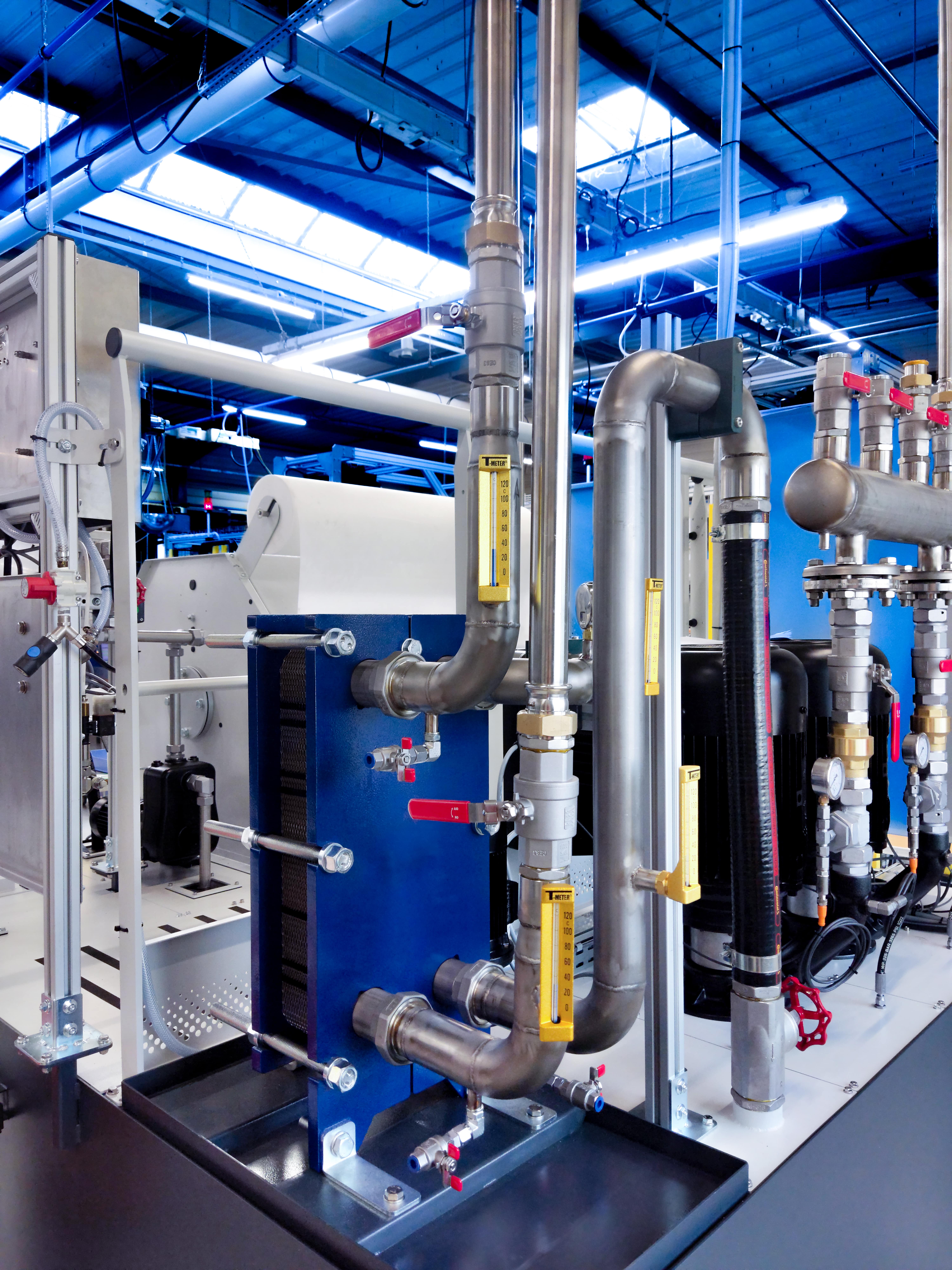

At SIEBEC, each filtration unit is engineered to meet the specific requirements of our industrial clients. The system presented here showcases our ability to develop compact, robust, and high-performance solutions, designed for high-efficiency automated environments such as those found in the machining of medical-grade titanium components.

An All-in-One Solution for a Demanding Environment

The objective: to ensure complete control of cutting fluids while delivering performance, reliability, and quality within a high value-added production process. The system simultaneously supplies 4 machining centers (turning and milling) and integrates a range of advanced technologies for optimized and autonomous operation.

Local Manufacturing and Expertise

Designed and assembled in Saint-Égrève (France), at our combined design office and manufacturing facility, this filtration system perfectly exemplifies SIEBEC’s commitment to providing each client with an industrial filtration solution precisely adapted to their operational requirements.

Industrial Expertise & Technical Partners

This project brought together advanced expertise across multiple areas :

-

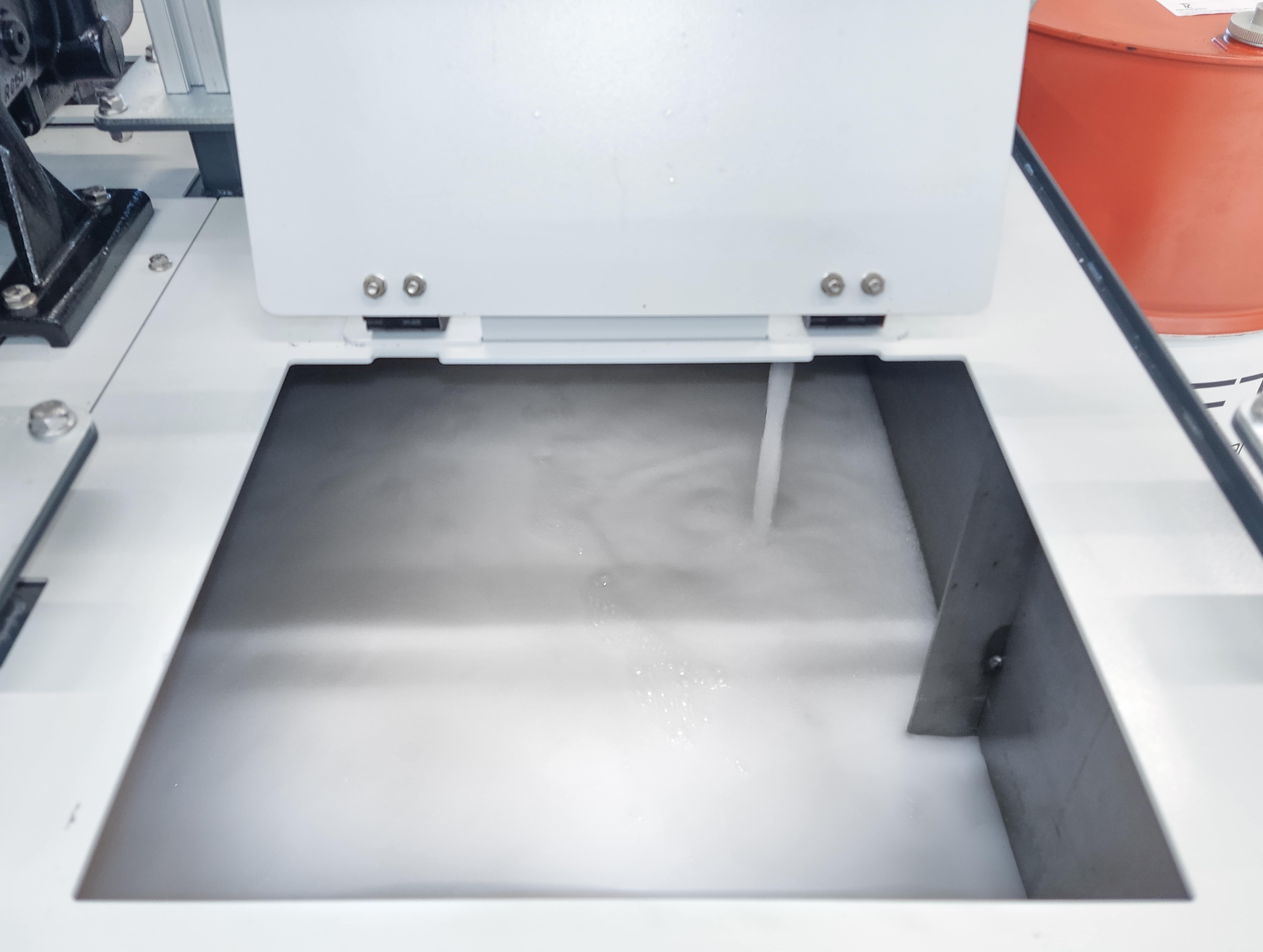

Continuous filtration using roll media

-

Oil skimming and antibacterial UV treatment

-

Thermal regulation of cutting oil

-

High-pressure coolant supply via remote booster pumps

-

Automated analysis and adjustment of soluble fluid concentration

-

Connected management via Industry 4.0 protocols

Two key partners contributed to this solution :

-

HENNIG: Belt conveyors with integrated disc filtration

-

SimonPAGE: Complete stainless steel piping system assembled by crimping

Technical Specifications of the Filtration Unit

-

Total flow rate: 480 L/min

-

Operating pressure: up to 70 bar

-

Fluid compatibility: suitable for titanium machining

-

Filtration: roll media + oil skimming + UV treatment

-

Coolant supply: low and high pressure with variable frequency drive

-

Industry 4.0 automation: connected control, automated concentration analysis and adjustment

-

Thermal regulation: stabilized cutting fluid temperature

A technical solution to a specific need

This achievement demonstrates our commitment to designing intelligent filtration systems that can be integrated into automated and demanding industrial processes. Thanks to complete control of critical functions (filtration, pressure, temperature, concentration), the plant ensures optimal production continuity while limiting human intervention.

Are you looking for a partner capable of designing a custom filtration solution for your processes?

8:00 -12:00 | 13:30 – 17:30