Respect environmental laws: recycle your effluents at lower cost

What is an industrial effluent?

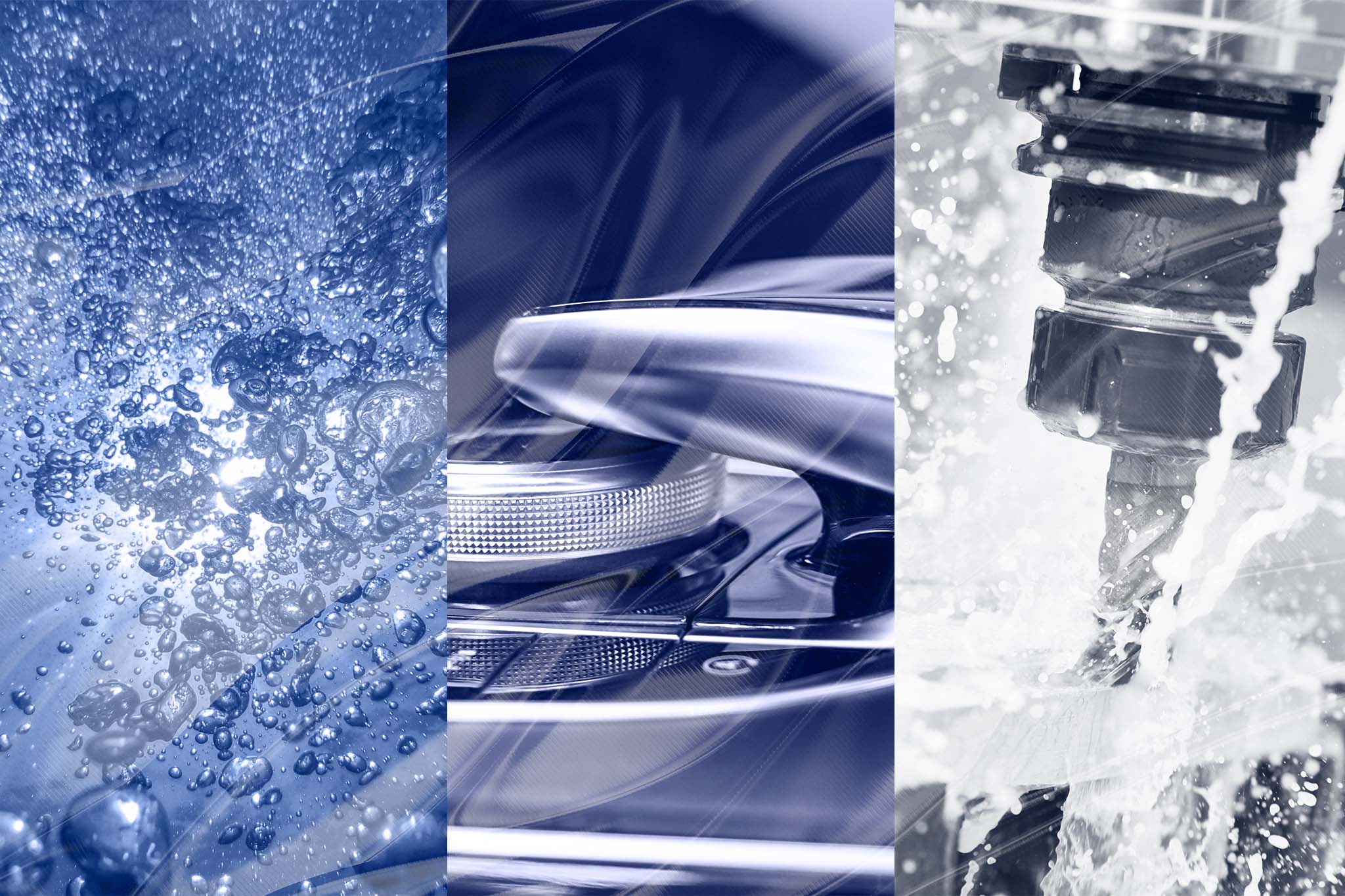

Industrial effluent refers to all liquids – often loaded with pollution – released by industrial activities.

Multiple sources of pollution

Almost all industrial processes generate effluents to be treated. Whether it is the manufacturing of products, the transformation of materials, the cooling of installations, the cleaning of parts (washing water), the cleaning of floors and machines, the surface treatment (painting, electroplating), the heat treatment, the chemistry… there is always a fluid to be treated at the end of a workshop.

The industry is responsible for most of ponctual toxic discharges.

(Source : French water agency)

We all have a role to play

Small workshops, as well as large factories, are all subject to the respect of environmental laws imposed at the local or national level.

How to reduce industrial pollution and invest in a green economy?

With global warming no longer a secret, industry has no choice but to take action for the planet. Industrial processes, which are very water-intensive, actually consume only a tiny fraction of it. This means that most of the water used is then returned to nature, either loaded with pollutants or with modified properties (composition, temperature, pH…), thus altering increasingly fragile ecosystems. It is this part of the water that must be treated.

10% of the water withdrawn in France is used by industry. Of these 4.5 billion cubic meters, only 7% is actually consumed.

(Source : French water agency)

The different configurations of effluent treatment

Treatment in a specialized wastewater treatment plant

Some effluents, generated in large quantities or too concentrated to be effectively treated on site, must be removed by tanker and then transported to specialized treatment plants. This is often the solution used by most companies wishing to comply with environmental standards, however these two steps represent a significant cost. But many companies are unaware that in many cases, a dedicated treatment plant on site can be sufficient to treat the effluents generated and eliminate these expenses.

On-site treatment

For simple effluents to be treated, an on-site treatment plant is very advantageous. It allows to treat the effluents on site, to potentially recycle the active ingredients in the process but also to avoid the costs of treatment and transport to specialized stations. At SIEBEC we have developed machines especially for this type of configuration. Discover the EASYPURE™, the ACIDPURE™ or the IONPURE™.

The cost of treating a polluted effluent is estimated at 0.5 to 5% of turnover, depending on the efficiency of the treatment system.

(source: French water agency)

SIEBEC solutions allow you a quick return on investment, in only a few months!

> Free study.

The most economical solution: reduce waste by recycling and reusing industrial effluents

Multiple applications

- Process / floor washing water

- Rinsing water loaded with particles or heavy metals (Zn, Ni, Pb, Cu, Fe, Cd, As…)

- Degreasing baths

- Cutting fluids

- Heat treatment

- Penetrant testing

- Tribofinishing

SIEBEC treatment & recycling solutions

Versatile or specialized, SIEBEC’s solutions meet many of the industry’s needs on a large or small scale.

Our customers see a ROI often less than 1 year!

Treatment of dissolved metals, COD, SS…