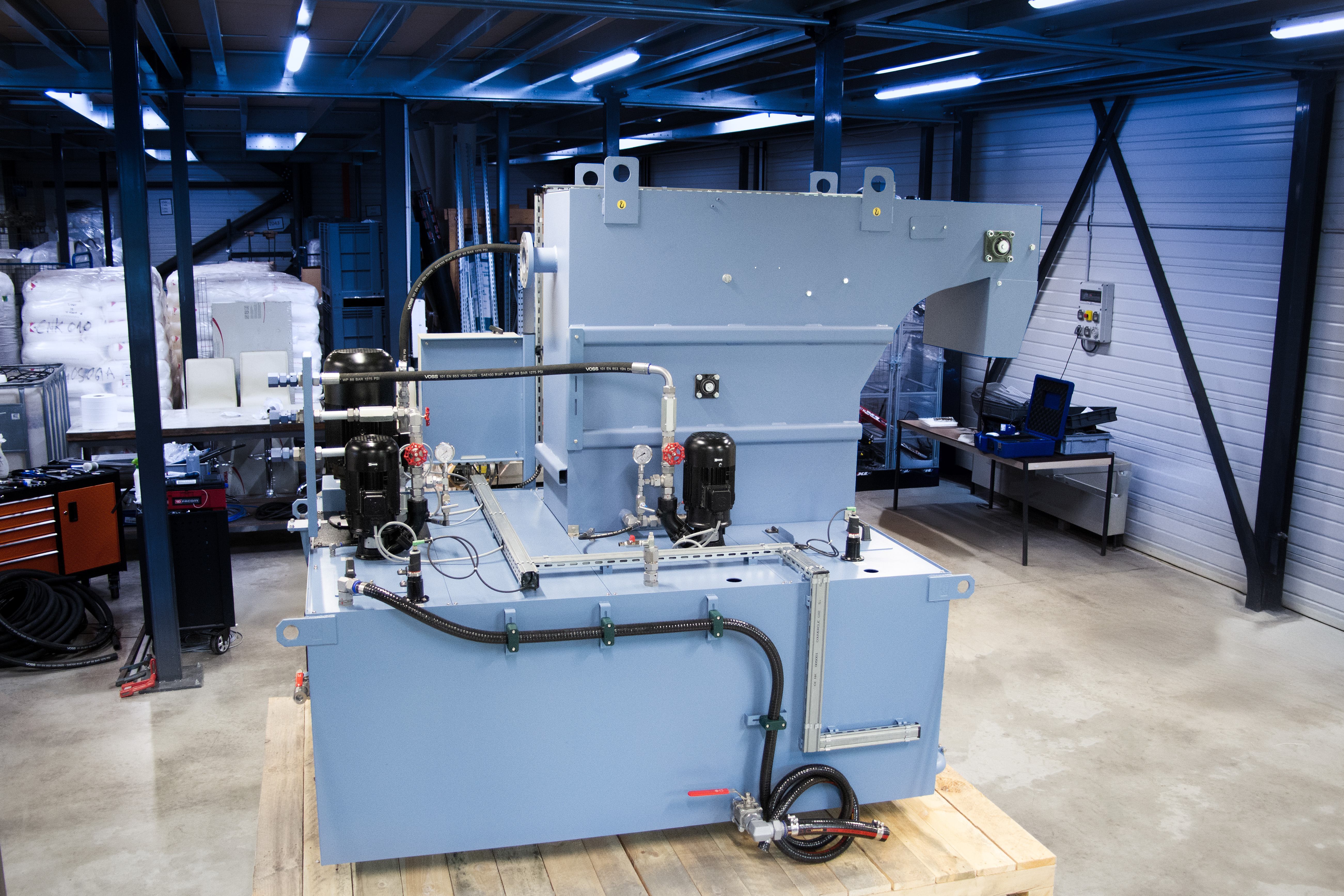

At SIEBEC, designing filtration systems goes beyond simply assembling components. We develop all-in-one, 100% customized solutions, engineered to fit complex and demanding industrial environments—such as aerospace parts machining.

Client Context

This system was developed as part of the retrofit of a large BERTHIEZ vertical lathe, used for machining aircraft engines.

The filtration and coolant system ensures the quality and cleanliness of the cutting fluids, providing a reliable and high-performance process for high-precision turning operations.

Key Features

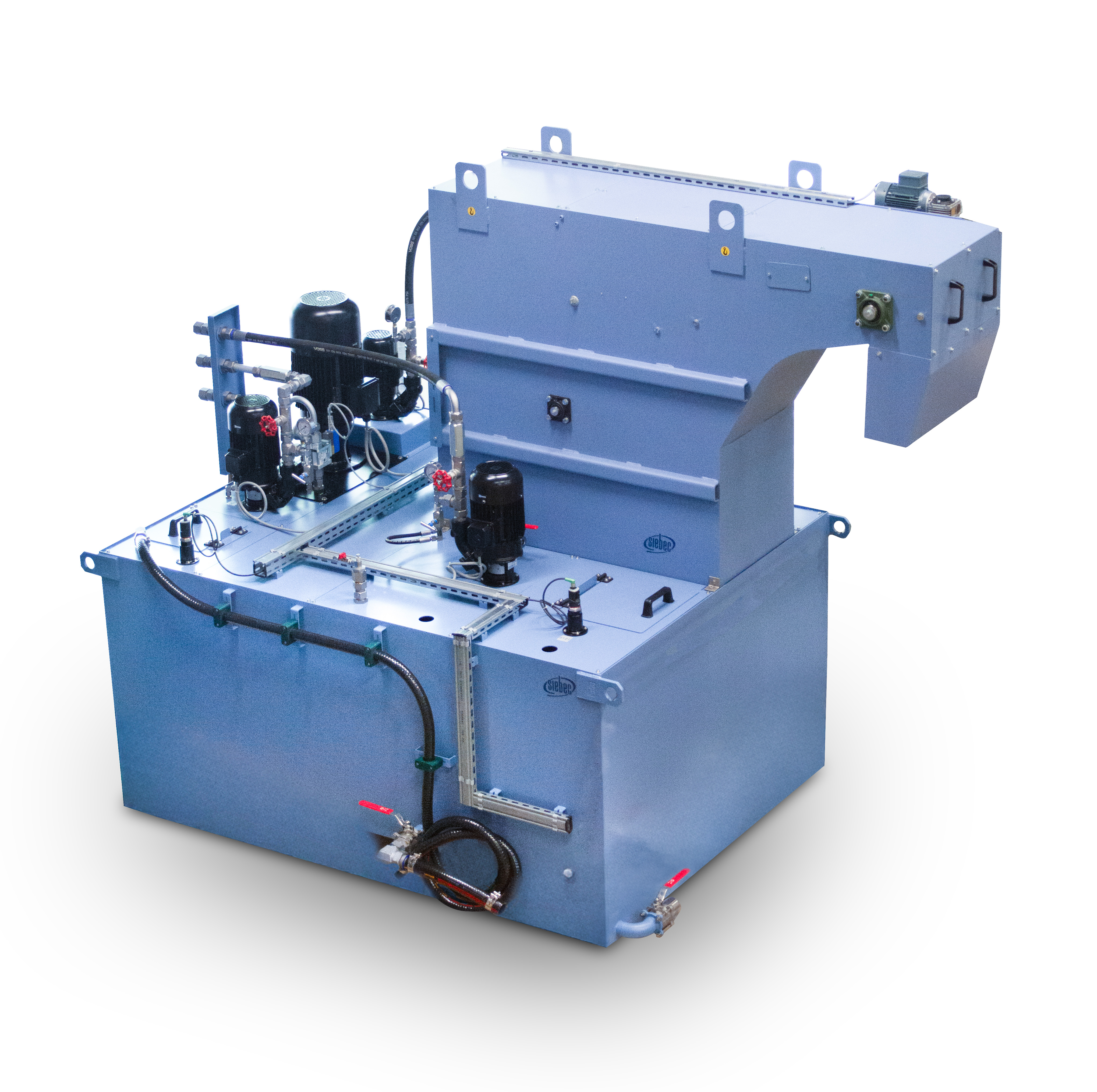

The goal : to provide a two-stage filtration solution, incorporating a final FILTECH cartridge filter to ensure optimal cutting fluid quality and long-term protection of the high-pressure pump.

The integration of a permanent filter medium also helps reduce operating costs for the client.

- Flow rate: 130 L/min

- Operating pressures :6 to 80 bar

- Process : Large-scale turning of aircraft engines

- Automation : Managed by the machining center

- Filtration : Rotary drum filter with permanent media (stainless steel mesh) at 50 μm + MINIPURE unit for fine FILTECH filtration and OILTECH oil removal

- Distribution : BP pump (semi-clean) + mesh cleaning pump + HP pump + BP pump (super-clean)

Local Manufacturing and Expertise

Designed and assembled in Saint-Égrève (France), at our combined design office and manufacturing facility, this filtration system perfectly exemplifies SIEBEC’s commitment to providing each client with an industrial filtration solution precisely adapted to their operational requirements.

Industrial Expertise

Leveraging deep expertise in critical environments (high-precision machining, technical metals, productivity and automation constraints), we support industrial players in designing turnkey systems that are scalable and robust.

A Filtration Solution Tailored for Aerospace Machining

At SIEBEC, each filtration system is designed as a unique, robust, and scalable industrial solution. This aerospace project demonstrates our ability to integrate multiple technologies into a single unit, while ensuring reliability, performance, and energy management.

Are you looking for a partner capable of designing a custom filtration solution for your processes?

8:00 -12:00 | 13:30 – 17:30